- Home Page

- Company Profile

-

Our Products

- Nickel Alloy Round Bar

- 01_Incoloy 825 Round Bar

- Hastelloy C2000 C59 C4 H - N Round Bars

- Inconel X-750 Round Bars

- Incoloy 925 Round Bars

- Hastelloy C22 Round Bars

- Monel 400 Round Bars

- Nickel 200-201 Round Bar

- Inconel 718 Round Bar

- Inconel 601 Round Bars

- Alloy 20 Round Bars

- 6m Hastelloy C276 Round Bar

- Nickel Alloy 200-201 Round Bars

- Inconel 600 Round Bars

- Alloy 286 660 Round Bars

- Inconel 625 Round Bars

- Hastelloy C276 Round Bars

- Monel Round Bars

- Hastelloy B2 Round Bars

- Alloy 926 Round Bars

- Inconel 718 Round Bars

- Incoloy 800H Round Bar

- Incoloy 800 DS 330 Round Bars

- Nickel Alloy 200 201 Round Bars

- Incoloy 800H 800HT Round Bars

- Incoloy 825 Round Bars

- Inconel 690 Round Bars

- Inconel Round Bar

- Hastelloy C276 Round Bar

- Hastelloy Round Bars

- Monel K 500 Round Bars Uns N0 5500

- Nickel Alloy Sheet

- Hastelloy B2 Sheets

- Inconel 601 Sheets

- Inconel 690 Sheets

- Incoloy 925 Sheets

- Inconel 600 Sheets

- Monel Sheets

- Hastelloy C22 Sheets

- Alloy 20 Sheets

- Nickel Sheets 200 201

- Incoloy 800 DS 330 Sheets

- Alloy 286 660 Sheets

- Hastelloy C276 Sheets

- Inconel X-750 Sheets

- Inconel Sheets

- Incoloy 825 Sheets

- Hastelloy B3 Sheets

- Alloy 926 Sheets

- Inconel 725 Sheets

- Nickel Alloy Plate

- Monel Plates

- Incoloy 825 Plates

- Inconel 625 Plates

- Inconel Plates

- Incoloy 925 Plates

- Nickel 200/201 Plate

- Hastelloy C2000 C59 C4 H - N Plates

- Alloy 286 660 Plates

- Incoloy 800H 800HT Plates

- Inconel 725 Plates

- Hastelloy Plates

- Inconel X-750 Plates

- Inconel 600 Plates

- Inconel 690 Plates

- Hastelloy C22 Plates

- Hastelloy B2 Plates

- Alloy 20 Plates

- Inconel 601 Plates

- Incoloy 800 DS 330 Plates

- Alloy 926 Plates

- Alloy 926 Tubes

- Hastelloy B3 Plates

- Nickel Alloy Coil

- Inconel 601 Coils

- Hastelloy B3 Coils

- Hastelloy C22 Coils

- Nichrome 80 X 20 Coils

- Inconel 600 Coils

- Alloy 286 660 Coils

- Hastelloy B2 Coils

- Nickel Alloy 200 201 Coils

- Inconel X-750 Coils

- Inconel 690 Coils

- Alloy 20 Coils

- Inconel 625 Coils

- Alloy 926 Coils

- Nimonic 75 80A Coils

- Inconel 718 Coils

- Hastelloy C276 Coils

- Inconel 725 Coils

- Nickel Alloy Tube

- Incoloy 825 Tubes

- Copper Nickel Alloy 70-30 UNS C71500 Tubes

- Copper Nickel Alloy 90-10 UNS C70600 Tubes

- Monel 400 Tubes

- Hastelloy C22 Tubes

- Alloy 286 660Tubes

- Inconel 690 Tubes

- Inconel 600 Tubes

- Inconel X-750 Tubes

- Alloy 20 Tubes

- Hastelloy C276 Tubes

- Inconel 601 Tubes

- Incoloy 800 DS 330 Tubes

- Incoloy 800H 800HT Tubes

- Inconel 625 Tubes

- Nickel Alloy 200 201 Tubes

- Hastelloy C2000 C59 C4 H - N Tubes

- Hastelloy B3 Tubes

- Nickel Alloy Pipe

- Inconel 600 Pipes

- Incoloy 825 Pipes

- Inconel 625 Pipe

- Inconel 601 Pipes

- Inconel 690 Pipes

- Copper Nickel Alloy 70-30 UNS C71500 Pipes

- Inconel 718 Pipes

- Inconel 625 Pipes

- Nickel 200/201 Pipe

- Inconel 718 Pipes

- Inconel 625 Pipes

- Hastelloy C276 Pipe

- Hastelloy Pipes

- Incoloy 800H 800HT Pipes

- Alloy 926 Pipes

- Nickel Alloy 200 201 Pipes

- Hastelloy C276 Pipes

- Incoloy 825 Pipes And Tubes

- Copper Nickel Alloy 9010 UNS C70600 Pipes

- Inconel X-750 Pipes

- Nichrome 80 X 20 Pipes

- Alloy 20 Pipes

- Inconel 600 Pipe

- Incoloy 800 DS 330 Pipes

- Hastelloy C2000 C59 C4 H - N Pipes

- Monel Pipes

- Alloy 286 660 Pipes

- Nickel Alloy Wire

- Hastelloy C22 Wires

- Alloy 20 Wires

- Incoloy 800H 800HT Wires

- Inconel 600 Wires

- Nickel Alloy 200 201 Wires

- Inconel 601 Wires

- Inconel 690 Wires

- Incoloy 825 Wires

- Inconel 725 Wires

- Monel 400 Wires

- Alloy 926 Wires

- Super Duplex UNS S32760 F55 Wires

- Inconel X-750 Wires

- Inconel 718 Wires

- Hastelloy C2000 C59 C4 H - N Wires

- Monel 400 Wires

- Monel K500 Wires

- Hastelloy C276 Wires

- Hastelloy B2 Wires

- Titanium Round Bar

- Titanium Tube

- Titanium Pipe

- Titanium Sheet

- Titanium Plate

- Titanium Coil

- Titanium Wire

- Stainless Steel Round Bar

- Stainless Steel Sheet

- Nitronic 50 XM 19 Sheets

- SS 904L UNS N08904 Sheets

- SS 17 - 4 PH Sheets

- SMO 254 Stainless Steel Sheet

- Super Duplex UNS S32750 F53 Sheets

- Super Duplex UNS S32760 F55 Sheets

- Duplex UNS S31803 F51 Sheets

- Nimonic 75 80A Sheets

- Nichrome 80 X 20 Sheets

- Duplex UNS S32205 F60 Sheets

- SMO 254 UNS S31254 F44 Sheets

- Stainless Steel Plate

- Stainless Steel Coil

- Stainless Steel Tube

- Stainless Steel Pipe

- Stainless Steel Wire

- Nickel Alloy Round Bar

- Contact Us

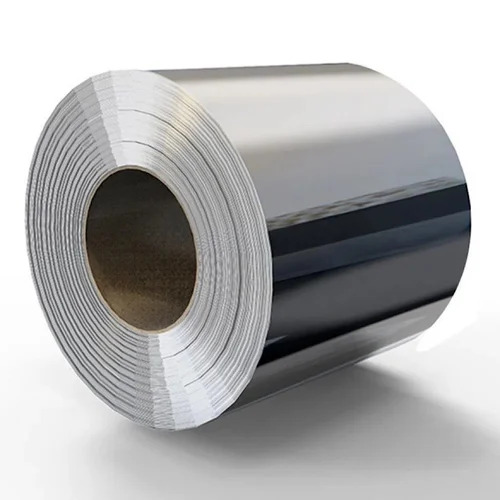

Inconel 725 Coils

3500 INR/Kilograms

Product Details:

- Purity(%) >99%

- Melting Point 1350-1400C

- Metal Type Nickel-Chromium Alloy

- Grade Inconel 725

- Usage & Applications Oil & gas industry, chemical processing, marine environment, sour well applications, and high-strength fasteners.

- Product Type Metal Products

- Material Inconel 725 Alloy

- Click to View more

X

Inconel 725 Coils Price And Quantity

- 3500 INR/Kilograms

- 100 Kilograms

Inconel 725 Coils Product Specifications

- 1350-1400C

- Metal Products

- Inconel 725 Alloy

- >99%

- Silver

- Custom as per requirement

- Oil & gas industry, chemical processing, marine environment, sour well applications, and high-strength fasteners.

- Ni (55-59%), Cr (19-22.5%), Fe (Balance), Mo (7-9.5%), Nb (2.75-4%)

- 1 Year

- Standard

- Plate

- Inconel 725

- 8.3 Gram per cubic centimeter(g/cm3)

- Nickel-Chromium Alloy

- As per coil specification

Inconel 725 Coils Trade Information

- 5000 Kilograms Per Month

- 7 Days

Product Description

Discover the latest Inconel 725 Coils, grandiose in their engineering and masterful in corrosion resistance, ideal for dominant industrial applications. Designed in accordance with ASTM B805 standards, these silver coils boast an advance purchase value for traders, suppliers, and importers in India. You'll find exceptional pitting and crevice corrosion protection, with a bright or matt finish and annealed hardness of Rockwell B90 max. With tensile strength that rises above 827 MPa and elongation minimums at 30%, it's a superb choice for oil & gas, chemical processing, marine, and sour well uses. Custom dimensions and a one-year warranty guarantee reliability.

Optimal Performance Across Challenging Applications

Specifically engineered for the oil & gas sector, chemical processing, and marine environments, Inconel 725 Coils deliver dominant resistance to pitting and crevice corrosion. The masterful alloy composition provides high strength, with an elongation of 30% min, supporting demanding application methods like fastener production and sour well operations. Their usage ensures lasting integrity in environments where low-grade metals might falter, offering reliability and safety in complex projects.

Expansive Export Markets and Efficient Logistics

Our Inconel 725 Coils serve both domestic markets and prominent international destinations at the lowest price. Consistent dispatching through major FOB ports like Mumbai guarantees timely delivery. Each coil is packaged meticulously to prevent any mar during transit, ensuring product quality on arrival. Custom dimensions and specifications are accommodated, making us a preferred supplier and trader, whether you are seeking small or grand shipments across the globe.

Optimal Performance Across Challenging Applications

Specifically engineered for the oil & gas sector, chemical processing, and marine environments, Inconel 725 Coils deliver dominant resistance to pitting and crevice corrosion. The masterful alloy composition provides high strength, with an elongation of 30% min, supporting demanding application methods like fastener production and sour well operations. Their usage ensures lasting integrity in environments where low-grade metals might falter, offering reliability and safety in complex projects.

Expansive Export Markets and Efficient Logistics

Our Inconel 725 Coils serve both domestic markets and prominent international destinations at the lowest price. Consistent dispatching through major FOB ports like Mumbai guarantees timely delivery. Each coil is packaged meticulously to prevent any mar during transit, ensuring product quality on arrival. Custom dimensions and specifications are accommodated, making us a preferred supplier and trader, whether you are seeking small or grand shipments across the globe.

FAQ's of Inconel 725 Coils:

Q: How do Inconel 725 Coils handle corrosive environments?

A: Inconel 725 Coils provide excellent resistance to pitting and crevice corrosion, making them highly effective for use in marine, chemical, oil & gas, and sour well environments where traditional alloys may degrade quickly.Q: What is the primary benefit of choosing Inconel 725 over other nickel-chromium alloys?

A: The masterful strength and grandiose corrosion resistance of Inconel 725 ensure dominant performance, especially in severe industrial applications requiring high tensile strength and extended longevity against aggressive agents.Q: Where can these coils be used most effectively?

A: They are ideal for oil & gas industry components, high-strength fasteners, chemical processing equipment, marine engineering projects, and sour well applications demanding durability and reliability.Q: What is the advance purchase process for obtaining Inconel 725 Coils from your company?

A: Simply contact our sales team for a quote and technical consultation. We ensure the lowest price, custom dimensions, and prompt dispatching after confirming your requirements and specifications.Q: When is the optimal time to use annealed Inconel 725 Coils in applications?

A: These coils perform optimally in projects demanding superior mechanical properties, such as tensile strength and toughness, especially where excellent corrosion resistance is required from the outset.Q: How are the coils packaged and shipped to prevent damage?

A: Each coil is securely packaged to eliminate mar during transport, handled through established FOB ports-primarily Mumbai-to guarantee efficient and safe dispatching to both domestic and global markets.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese